Straw Pellet Production Line can Turn Waste Straw into Useful Pellet

Work with straw pellet production line

Straw pellet production line in GEMCO is a set of equipment which we are pushing recently. As we all know, straws including corn stalks, cotton stalks, soybean straw, rice straw, wheat straw, sawdust, wood flour, rice hulls, peanut shells, sweet potato vine, alfalfa and canola straw can bum rubbish before. However our R&D personnel put their hearts into it and change waste material into things of value to make them burn. As a result, straw pellet production line emerges as the times require. Working with it is a simple thing, at the same time, is also a pleasant stuff because of its excellent performance and characteristic.

Characteristic of straw pellet production line

- High efficiency. With scientific design and reasonable structure, our straw pellet production line forbids external disturbance at the most extent in order to achieve efficient pellet making and efficient pellet burning. Apparently, we did it. With less manpower and material resources inputting, our straw pellet production line could create more chance to obtain revenue maximization.

- Thrift. Thrift is what we always pursue. As for the straw pellet, raw materials such as sawdust, wheat straw and rice straw, they come from trash in farm or construction site. No matter how much we use, there is no waste and squander. Next is the equipment itself, GEMCO provides different kinds of straw pellet production line with different engine power. All of them adopt principle of energy saving, so they are low energy and high efficiency.

- Environment friendly. Today most enterprises strive for making their productions adapt the policy of environment friendly. So do us. Production in GEMCO shows highly environmental protection property whose raw materials are biomass resources and engine power is low emission and little pollution, not to mention the discharge of smoke, sulfur and nitrogen, even carbon dioxide whose discharge is zero.

- High profit. Your profit is our harvest. Put into cost that needn’t too much because of those cheap but valueless biomass raw materials, the profit you will gain is inestimable. Combines above, high efficiency means profits that one straw pellet production in GEMCO is higher than others with same quantity of input; thrift means saving in both energy and resources while keeping high quality which makes high profit; as for environment friendly, just to do this is a success for the environment and human beings, which is moreover than profit.

- After sale service is guaranteed. The customer is king whose degree of satisfaction is our persistent pursuit. So GEMCO ‘s after sale service is with you from you own a straw pellet production line. Whatever you want to know about, please let us know and we will give you the best answer as fast as possible.

Working principle of straw pellet production line

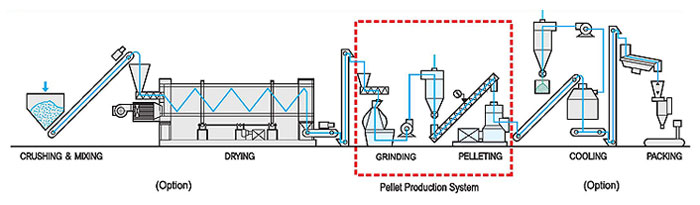

Though straw pellet production line is a set of pellet equipment, its principle is not too complex. Let’s learn about the working principle of straw pellet production line. Firstly, store straw materials with chipping them and put them into the cyclone . Secondly, dry them to make sure their burning efficiency. Then turn to next link, grind those straw materials again through a storage to make them into a dry and pure degree. Next is pelletizing process which changes straw materials into pellets in regular size and smooth surface to guarantee their combustion rate. And after doing so, cool them. The last step is packing. The packing machine packs those straw pellets in bags in order to storage and delivery easily.

If you would like to know more about it, please contact us right. We are waiting for your e-mail.