Pellet Press Roller

- Model: 150, 200, 230, 260, 300 type

- Power: 10-41 HP

- Capacity: 40-800 KG/H

Go to detailed rules for FREE test Raw Materials can be Pelletized

The importance of pellet mill rollers

GEMCO pellet presses have advantages in their exterior design, humanized operation mode and comprehensive service. In particular, the superior spare parts they adopt ensure good performance. Roller and flat die are core parts of pellet press. Pellet mill rollers are easy to wear, whose quality determines the service life of pellet presses.

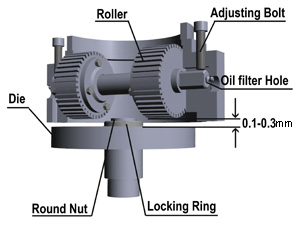

Working principle of pellet mill rollers

Rollers play an important role in producing biomass pellets. There are R type and D type rollers. R refers to roller rotation, while the flat die keep still. On the contrary, D type contains a stationary roller and a rotating die. When flat die pellet press works, there forming strong friction between the roller and flat die. Under high pressure, raw materials are squeezed into holes on the flat die and come out in the shape of strips. Then there are blades cutting them into length we need.

D type pellet press roller

R type pellet press roller

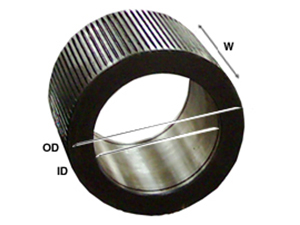

Pellet press roller inside

Pellet press roller structure

The stiffness of roller has direct impact on the producing performance of pellet press. Usually, there is a steel shells covering the pellet mill rollers. Their high stiffness and rough surface ensure the intensity of extrusion. Because of frequent friction with the die surface, they are wearing parts in pellet press.

GEMCO has made great efforts to increase the durability of rollers. We adopt high-class alloy steels to the rollers, with the lifespan up to 1000 hours, which has passed the ISO9001 and CE international certification. Years of technology accumulation enable us to produce top-class rollers and other spare parts.

Advantages of GEMCO pellet mill rollers

- The roller is made of 42CrMo alloy steel, whose high stiffness ensures long lifespan and good production performance.

- The working duration of our roller is 1000 hours. When it wears out, we recommend you to buy original spare parts from us.

- GEMCO is able to provide rollers of different dimensions to meet processing demand of various materials.

- We offer thoughtful pre-sale and after-sale service, ready to meet any of your request. We guarantee timely delivery.