Daily maintenance and solutions to common troubles of straw pellet machine

Straw pellet making machine has been one of the well-known biomass machine in rural area, but there are still lots of farmers are not aware of the advantages of the straw pellet making machine, which may because of these two reasons: on the one hand, they are worry about the high cost of investment, high production cost and large power consumption; on the other hand, they worry that they can’t operate the straw pellet making machine masterly so that the the fault of machine can’t be solved in time.

There is no doubt that the maintenance of straw pellet making machine is important, but the reality is that many users don’t know how to maintain the machine properly. According to our decades of experiences in pellet making machine manufacture and sales, we have accumulated a large number of experiences on pellet making machine maintenance. Today, I will share you some common troubleshooting and machine maintenance skills.

Common maintenance methods for pellet making machine

Lubrication and cooling of roller

A roller in the straw pellet making machine is used to press raw materials into the hole of die, push the back material forward so that material in front can be formed into pellet. Therefore, working temperature of the roller will be very high, timely and reasonable oil support and heat loss are indispensable, which can effectively prolong the service life of roller and capacity in the effective time.

Grind

Before use, the new straw pellet making machine or machine with a new roller and die should be fully ground. As the mould, die and roller of straw pellet making machine are all heat treatment parts, there will be produced some burrs in the inner hole of the mould during the heat treatment, which will hinder the flow and moulding of raw materials during the pelletizing of straw pellet.

Inspection and replacement of wearing parts

Because of the high working strength and load bearing of roller and die, the straw pellet making machine should be continuously tracked and monitored, including current, voltage, noise, dust, pellet status, amount of oiling, etc. Then according to the actual situation of wearing parts, suit the remedy to the case, then deal with the failure in time ant replace the damaged parts quickly, in order to guarantee the continuity of production process.

Prevent the internal parts of straw pellet making machine from getting wet

If the motor of straw pellet making machine doesn’t be used for a long time, it must be removed and kept in where is clean and ventilated. As the straw pellet making machine is made of steel, it is easy to rust if kept for a long time, and greatly reducing the service life of straw pellet making machine.

Clean

Last but not least, when the straw pellet making machine is finished used or stopped, powder that remains in the interior should be clean, prepare for the next use.

How to do when the straw pellet making machine has no oil out?

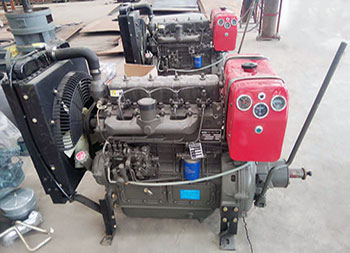

There are two power sources of straw pellet making machine, electric power and engine oil. The synergistic of these two power sources is the basis for ensuring the stable operation of the straw pellet making machine, therefor, once the machine has no oil support, it will fail and need be maintained timely.

Maintenance includes the following several contends:

- Check if there are raw material left in the straw pellet making machine, especial the gap between the principal axis and rotor.

- Remove the strainer from the oil filter in the straw pellet making machine and clean it carefully, to prevent impurities blocking the mesh and influence the filtration effect.

- Remove the grease slider of straw pellet making machine, in order to clean impurities stuffed into the hole.

Chose GEMCO pellet making machine, give you professional technical support.

GEMCO can manufacture not only large and medium scale straw pellet making machine, but also small straw pellet making machine, which has the advantages of less investment, easy operation, small area, and low power consumption. Raw materials are easy to get in rural like corn, straw, grass and other cheap waste biomass material. As to the technical support, GEMCO has a professional technical maintenance team who can provide free technical support for you, helping you solve the problem appearing in the use. So, if you are interested in making straw pellet by your own, but worry about the following technical and maintenance problem, please feel free to contact us, GEMCO is your ideal choice that will not regret!

Click your interested straw pellet making machine for more details!