Small pelletizing plant plays an important role in biomass machinery

In today society, the economy grows rapidly, while we are facing the pressure about energy security, energy economy and energy environment. It is an inevitable choice to exploit renewable energy sources actively including hydroelectric, wind power, solar energy and biomass energy to achieve economy sustained and healthy development. At the same time, many industries advocate a high efficient and environmental friendly production models. The appearance of pelletizing machine is a huge achievement to improve this problem. As a result, going with the stream of biomass machinery market, now GEMCO has pushed out a new product called small pelletizing plant.

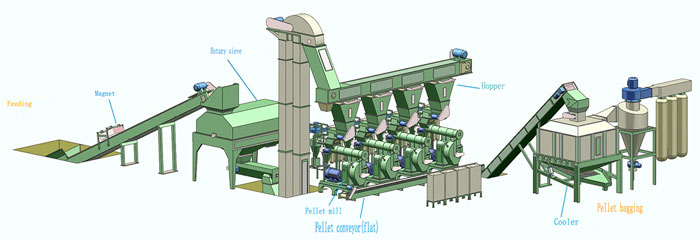

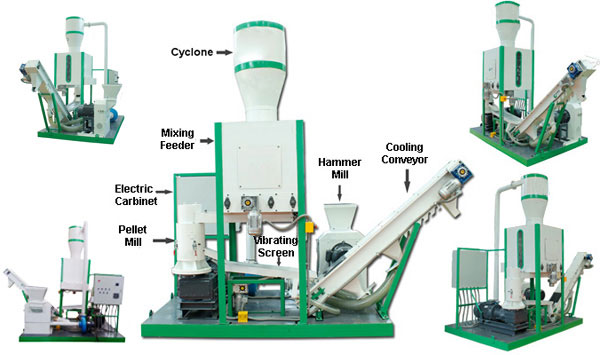

Small pelletizing plant is an equipment that made of a set of pelletizing separate parts which makes waste materials into flammable pellets so that improves efficiency of burning. It uses waste and rubbish as raw material, such as sawdust, alfalfa, peanut shell, hay, straw, wood chip, wood shavings, coconut shell, rice husks, etc. It has many assembly parts, they are cyclone, mixing feeder, electric cabinet, pellet mill, hammer mill and cooling conveyor, which could accomplish a complete set of pelletizing process, for instance, crushing, drying, pelletizing, cooling, even bagging if you opt.

Our small pelletizing machines possess a large number of repeat customers for its high quality and efficiency, low cost and environmental design philosophy so that it plays an important role in not only biomass machinery, but also agriculture and manufacture industry.

The reason to choose small pelletizing plant

- Our small pelletizing equipment is made from high quality alloy steel materials with superior design and technology so that it is durable to serve for a longer time. At the same time, every link in this plant system is very safe on account of our engineers design many safety locks and stop buttons from the beginning.

- As you can see, small pelletizing machine is an all-in-one machine which contains the whole process to make pellets, even little details. The advantage are saving a lot of manpower and material resources from every link. Meanwhile these energy and power could reduce the cost and change them into profit.

- At this point, we have to refer to the profit. There is no doubt that our small pelletizing would provide you and your team a rare choice to make money and benefit. Purchase it in a effective cost, apart from essential investment, for example the cost of raw materials and electric, the rest are gain.

- The pellets made by small pelletizing plant have a high burning rate. According to crushing, drying, pelletizing and cooling by the plant, these pellets achieve a dry and pure state, what’s more, they also have smooth surface. Little moisture and impurity make burning more efficiency.

- As we all know, air pollution is what we most concerned about when burning fuel. It’s OK. The entire raw material after processing by our small pelletizing equipment reduces the discharge of smoke, sulfur and nitrogen, not to mention carbon dioxide whose discharge is zero.

- Low cost of raw materials is a outstanding characteristic about small pelletizing machine. Straw, wood chip, wood shavings, coconut shell and rice husks, we could find them everywhere in the farm or somewhere. It is our duty to change these valueless waste into useless biomass raw material, next into profit. With little cost you paid, a great profit you will gain.

GEMCO has the ability to manufacture the pelletizing machine with various of specifications you need, so if you need a pelletizing machine or small pelletizing plant, please feel free to contact us, we are ready to help you!