Do you know the pelletizing process for wood pellet fuels?

Now I briefly introduce how to make wood pellets. If you're interested in the pelletizing process or you want to make your own wood pellets, the article can help you. There are many raw materials of pellet fuels, such as wood, paper, corn, alfalfa, straw, grass, domestic garbage, agricultural wastes and so on. In this article, we mainly introduce the pelletizing process of wood, but the pelletizing process is basically the same for other raw materials.

Brief introduce of pelletizing process

Recently, small pellet machine is an ideal choice of household and small scale industry.

In the pelletizing process, Crushed raw materials enter the pelletizing room through the hopper and then they are forced to be extruded from the holes of flat die at a fixed diameter, so the dense pellets are made. Meanwhile, heat produced by compression and friction can melt lignin in wood. When pellets emerge on the other side of the die, the lignin colds slowly and cements all materials to produce hard pellets.

Complete pelletizing process for wood pellet fuels

- Crushing, all raw materials need to be crushed to very small. If the material is like sawdust, you can skip this step. Wood or other small pieces can be further crushed by hammer mill.

- Transportation of raw materials. Once the raw materials are crushed, they must be transported to the dryer. There are several ways to transport these raw materials, namely, screw conveyor, conveyor belt, and vacuum system. Screw conveyor is the most common support machine.

- Drying. Generally, the moisture content of raw materials should be between 10%-20%. Drying the raw materials to a proper moisture content is critical to the production of high quality pellets.

- Mixing. To make homogeneous pellets, homogeneous raw materials is important. If the raw materials have the same humidity and density, the mixing is unnecessary. Other raw materials from the dryer may have different humidity and density, you need a batch mixer for these differences.

- Pelletizing. Using flat die pellet press, the raw materials are compressed and compacting by the relative movement of flat die and roller, then the blade cut them into pellets with the same size.

- Sieving and cooling . Not all pellets are available, some may be broken into small pieces, so the sieving depends on the quality of pellets. When the made pellets leave the pellet press, they are too hot and also release the steam, so cooling and drying is necessary. The most common method is air drying, of course, you can use blower or fan. Besides, in order to prevent the cracks, you need to notice that the speed of drying can not too fast.

- Transportation and storage of pellets. When the pellets are cool, they will be transported to the packaging equipment. In the process, usually using bucket elevator because screw conveyor can damage the pellets. At this time, the pellets have been completed and are ready to be used. However, they need to be stored and shipped to consumers in most cases. The storage of pellets must be kept away from moisture. If the pellets absorb moisture, they will become expansive and useless.

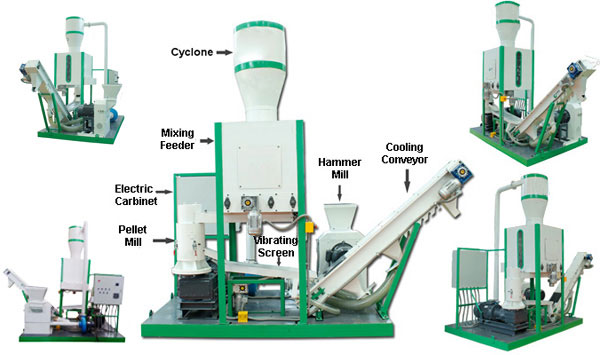

GEMCO small mobile pellet plant

GEMCO small mobile pellet plant is a multifunctional small mobile pelletizing system and our new pelletizing equipment, which includes all necessary equipments, such as hammer mill, separation system, pneumatic handing system, mixture feeder, tempering system, facility for pelletizing, cooling system, conveying mechanism and etc. Complete pelletizing process can be achieved by one machine. It’s cool!