how to prolong the life of pellet press dies

There are many factors that influence the die life of pellet press, only when know these factors, we can make some measures to prolong the lifespan of dies. The main factors influencing die life during pellet production are as follows:

- Composition of raw materials (formulations)

- Properties of raw materials used in particle production

- Fat content

- Particle size of ma liquid

- Water content before granulation

- Thermal regulation of the paste

- Automatic/manual control of particle grinder

Composition: fiber-rich compositions are more difficult to precipitate than rabbit feed, and therefore die life is shorter: for example, If the life of the dice used to prepare the rabbit feed is 1, the life span of the dice used in the preparation of the rabbit feed is 4 cattle feed and 5 when used in poultry feed.

Features of raw materials: materials containing silica / sand wear fat faster: formula containing 1.5-2% fat runs smoother, less abrasive, fat acts as a lubricant.

The size of ma liquid: the larger particles of ma liquid are more abrasive, the water content and heat of ma liquid are regulated: the dirty ma liquid is dry and difficult to granulate.

Control: the operator shall regularly check the wear of the deflector and scraper and the adjustment of the roller: avoid uneven wear of the die, resulting in invalid granulation.

Wear state of regulator: ensure effective preconditioning.

Steam traps and filters: ensure that no condensate flows into the regulator.

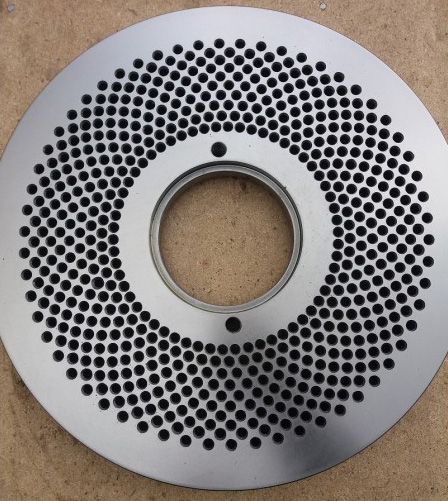

Make sure that the rollers are correctly adjusted: the minimum distance from the die must be 0.2-0.3 mm. The wrong setting of the rollers can cause the contact between the rollers and the die. This may cause 'roll over' of the holes in the die - deformation and partial closing of the holes

When changing dies, carefully assess the condition of the die seating surfaces and of the fixing systems (collar, clamp or wear ring). Careful: if the die is not properly fixed it can break.

The die clamping rings should be checked every time a new die is put on the pellet machine, especially for those dies designed with big flanges. From experience, in the majority of cases where a die has broken the cause has been due to a worn out or defective clamping ring. Dies running with a defective clamping ring can give rise to strong vibrations, die breakage and reduced die life.

How to prolong the lifespan of pellet press dies

Make sure the roller is adjusted correctly: the minimum distance from the die must be 0.2-0.3 mm. Incorrect wheel setting will result in contact between the roller and the die. This can cause holes in the mold to "roll over"-deforming and partially closing the holes.

When changing the die, carefully evaluate the condition of the mold seat surface and the fixing system (circlip, circlip or wear ring). Be careful: if the dice is not properly fixed, it may break.

Each time a new die is placed on a granulator, the clamping ring should be checked, especially for dies designed using large flanges. According to experience, in most cases, die damage is due to wear-off or defective ring. Defects in the clamping ring will lead to strong vibration, die breakage and shorter die life.