Flat Disk Pellet Mill Help You Make Money from Biomass Waste

As an environmental protection equipment for the utilization of biomass pellet fuel, flat disk pellet mill is becoming more and more important in our production and daily life. Utilization technician of biofuel has gradually matured in various of industries, which has further promoted the investment of flat disk pellet mill. There are still many customers who want to invest biomass pellet production but don’t know much about the flat die pellet mill.

As an environmental protection equipment for the utilization of biomass pellet fuel, flat disk pellet mill is becoming more and more important in our production and daily life. Utilization technician of biofuel has gradually matured in various of industries, which has further promoted the investment of flat disk pellet mill. There are still many customers who want to invest biomass pellet production but don’t know much about the flat die pellet mill.

According to the years of experiences in biomass pellet mill, I’ll share some problems that our customers are most concerned about when purchasing flat disk pellet mill.

Characteristics of flat disk pellet mill

- Compared with ring die pellet mill, flat die pellet mill has larger space as they aren’t limited by the wheel pressure and mould. Thus when it pelletize the crude fiber material, the mould is more durable, increase the mould rate. The pelletizing press of flat disk pellet mill can be adjusted, pellet density is large, and both side of the mould can be used, the output is stable.

- Pellet mill material is wear resistant high alloy material, internal structure uses advanced technology.

- The bearing has strong pressure bearing capacity, the roller is fully sealed to prevent dust from entering.

- The shell of flat disk pellet mill is made of nodular cast iron. It has high strength and is not easy to deform.

- Flat disk pellet mill has advantages of good stability, high yield, less power consumption, cheap price, easy operation, easy to move. When there is no electric power facilities, you can choose a diesel engine flat disk pellet mill to replace.

- The material of flat disk pellet mill is shaped once after compression, doesn’t need to add any material.

Working principle of flat disk pellet mill

Our flat disk pellet mill adopts double-stage driving of belt, worm and gear, transform is stable and the noise is low. According to the movement state of executing parts, flat disk pellet mill can be divided into roller type and die type, the latter is often used in small flat disk pellet mill, while roller type is often used in larger scale pellet mill.

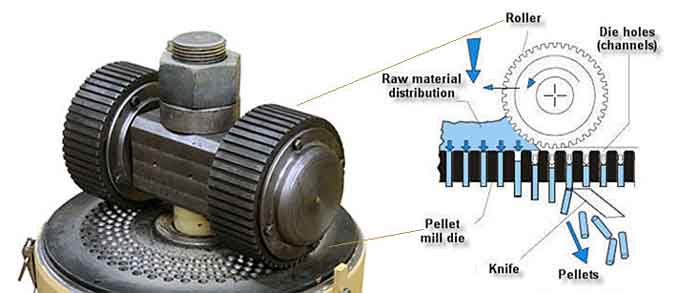

Flat disk pellet mill drives the principle axis through the reduction gearbox, principle axis drives the roller, when the roller makes revolution around the principle, it also revolves on the its own axis. When process pellets, biomass raw materials are fed into the feed room of flat disk pellet mill, and spread evenly on the flat under the combined action of distributor and scraper. The principle axis drives the roller to continuously roll over the material layer and squeeze the material into die hole, after a period of molding and maintenance in the die mould, raw material will be extruded in cylindrical form, then the rotary cutter cuts off the material, finally form into pellets.

Is the investment of flat disk pellet mill large?

Many customers are interested in investing in flat disk pellet mill, but they are still worry about the investment cost and the further returns. Through the following analysis, many customers may have a further understanding.

- Raw material is cheap. Materials used in producing pellets are various waste biomass material, such as straw, grass, stalk, sawdust, rice husk, paper, alfalfa, coconut husk, and so on. These materials are very common in rural areas, in where they are burned as waste, now you can make them into pellet, which can be used as fuel or poultry feed.

- Low labor cost. Our flat disk pellet mill is easy to operate, just one people can complete all operations, greatly reduce your production cost.

- Consumable parts cost low. Consumable parts mainly refers to some wearing parts and other parts of flat disk pellet mill. These parts are easy to wear in the pellet making process, need to be replaced regularly. GEMCO flat disk pellet mill adopts high quality wear resistant steel to produce these parts, whose wear rate is much lower than that of peer products.

- Increase your revenue. Use biomass waste to produce pellets, you not only don’t need to spend money on these waste treatment, but also can have an extra income. These pellet fuel have higher burning rate, reduces your burning cost, what’s more, feeding poultry with pellet is more conductive to nutrient absorption.

Through the above introduction, you must have more understanding on the flat disk pellet mill. Undoubtedly, flat disk pellet mill is a machine with less investment and much revenue. If you decide to invest a flat disk pellet mill to make you own pellets, contact us now, we are ready to help you increase your income!