Build your own pellet production line

You should already have sufficient supply of raw materials, such as wood, tree branches, grass and so on. The size, shape and moisture content of your raw materials will affect the quality of pellets, but they aren’t ideal in general. Therefore, larger pieces of materials should be pulverized by a set of hammer mill, wet materials must be dried by a dryer, and dry materials must be added water.

What’s more, pellet production line can increase output, save labor, and reduce production costs. Pellet mill is essential to make biomass pellets by yourself, but it is far from enough for building a pellet production line. For the users who want to run their own pellet production business, a complete pellet production line is absolutely necessary.

What is pellet production line?

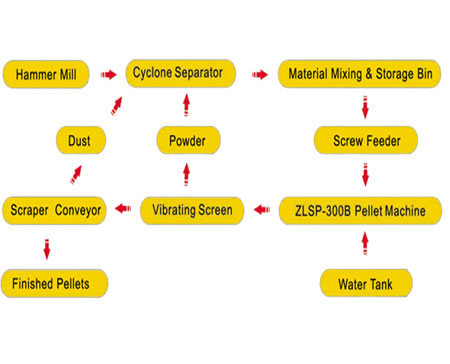

Pellet production line, special equipment for manufacturing biomass pellet fuel, is mainly composed of hammer mill, separator, drying system, pellet mill, vibrating screen, conveyor, cooling system, automatic packing machine, etc. The pellet production line has more functions than pellet mill, which include crushing, cooling, transporting and etc.

The pellet production line can process twig, bark, wood, sawdust, straw, rice husk and other biomass waste. The made pellets can be used as effective fuel of industrial boilers and civilian stoves.

Pellet mill and other support equipments

Pellet mill is the main equipment that you must have for building pellet production line. Hammer mill can process wood chippers, corn straws, and other raw materials into smaller pieces, whose size is prepared for making biomass pellets. Drying system can be used for drying a wide range of biomass materials such as manioc waste, colza cake, leaves, alfalfa, straw, sawdust, marigold, wood shavings, etc. As different raw materials have different moisture, a dryer is crucially important to pellet production line. Pellets come from pellet mill are with high temperature, the function of cooling system is to cool down the temperature. In order to crush raw materials expediently, the crusher is placed in a low position to input raw materials conveniently. After crushing the raw material, there is an altitude difference with the feeding port of pellet mill. If the manpower is adopted, the production efficiency will be greatly affected. If you want to set up a complete pellet production line, conveyor is your essential choice.

GEMCO pellet production line for sale

If you’re thinking of building your own pellet production line you have come to the right place. It is not difficult to build your own pellet production line. GEMCO small mobile pellet plant is a complete pellet production line, which has become a new choice of the majority of customers.

Characteristics of GEMCO multifunctional mobile pellet production line

GEMCO multifunctional mobile pellet production line is often called GEMCO small mobile pellet plant. As a complete pellet production line, it is an integrated system with pellet mill and other supporting equipments.

- Firstly, you don’t need to choose multiple machines for a complete pellet production line.

- Secondly, GEMCO small mobile pellet plant is flexible that it can move to anywhere, what’s more, the volume of the small mobile pellet plant is small and favorable for transportation.

- Thirdly, it can be operated just by adjusting the buttons, so only one people can operate it.

- Last but not least, it will greatly help you save the budget, as GEMCO small mobile pellet production line is cheaper than general pellet production line.

Contact us

If you want to know more information about our pellet production line, please visit our website or contact us directly. We offer 7/24 email and phone cell service. GEMCO is ready to answer your any questions about our small mobile pellet production line.