Biomass pellet mill, build your future

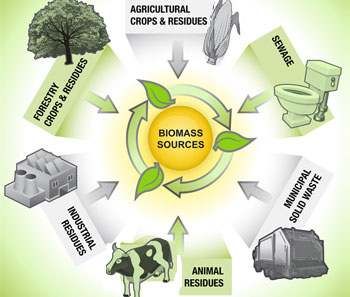

Biomass energy is relative to the conventional energy, it is renewable and known as biofuels. It can be used widely, with the development of science, and the more and more serious pollution of environment, the biomass energy sources are very wide, for instance, many of the biomass fuels we used today come from wood products, crop residues, dried vegetation, wood chips, wastes and so on. Biomass energy is a harmless energy which belongs to clean energy. Then how to make the biomass energy into our life, that needs the biomass pellet mill to process so many raw materials into biomass pellets.

With the increasing price of fossil fuels as well as the more and more serious environmental pollution, people began to pay attention to the renewable and biomass energy, they finally found that biomass pellets are the prefect alternative, so that’s why biomass pellets are so popular, accompanying the biomass pellet mill is hot sale now, GEMCO mainly offer you the flat die pellet mill for homemade pellets or small scale industry.

Advantages of biomass pellets

What is biomass pellet mill?

Now that biomass pellets are in great demand, biomass pellet mill is the main equipment to process pellets. It can be divided into flat die pellet mill and ring die pellet mill. Our company, GEMCO mainly produces flat die pellet mill. Such as flat die pellet mill with electric motor, diesel engine, gasoline and PTO. The ring die pellet mill mainly suitable for the large scale industry. But our flat die pellet mill can be used at home, only one person can operate it.

The production capacity of our pellet mill is different, there are many reasons, as a matter of fact, there are different yield of biomass pellet mill due to the characteristics of different raw materials as well as their moisture content.

Characteristics of biomass pellet mill

- Our flat die pellet mill with electric motor is equipped with three phases electric motors. one for driving the conditioner, one for driving the pelletizing chamber, another for pushing the raw material into the pellet mill.

- We have the advanced feeding system, which can automatically convey the raw materials into the feeding hopper smoothly and evenly to prevent blockage.

- The pelletizing system adopts oil adding system to realize the lubrication of main shaft without stopping the machine, which guarantees the constant work of biomass pellet mill.

- GEMCO pellet press is superior in its scientific design, reliable quality, compact structure, small friction, low energy consumption, high yield and low cost.

- Comparing with competitors in the field in china, the energy consumption of our products are 30% lower than others.

- The pellet machineries adopt world advanced gear power transmission technology (which is also used by CPM). Compared with belt power transmission technology, the working efficiency gets 15% up, while the attrition 30% down.