About biomass pellet machine production line

What is biomass pellet?

The biomass pellet is the cylindrical small particles which is made by pellet making machine. Usually, the raw material of the biomass pellet is the crushed powder of the biomass straw, forestry waste materials and etc. Under the condition of normal temperature, biomass pellet is finished by the roller and mold to dense cold forming the raw material. The density of material generally is 0.1-0.13 t/m3, the finished pellet density is 1.1 1.3 t/m3, it is convenient for storage and transportation, and greatly improved biomass combustion performance.

The use of biomass pellet making machine:

- Can be used as the feed of large livestock farms, it is convenient for storage and transportation;

- Can be used for civil heating and life energy, it is clean and no pollution, convenient for storage and transportation;

- Can be used as industrial boiler and furnace fuel, it is alternative to coal and gas, to reduce environmental pollution;

- Can be used as gasification power generation and fuel of thermal power generation, to solve the problem of shut down the electricity for small power plant.

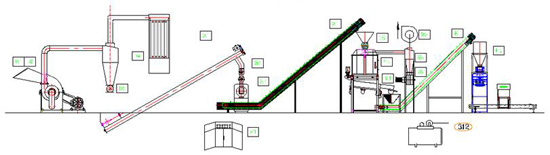

What is biomass pellet production line, and its production process ?

In general, a complete production line consists of the following equipment: crusher, dryer, pellet making machine, cooling machine and packing machine. From the original crushing to the final packaging, It completes the whole process from raw materials to packaging. The detailed process as follows:

- First to make the raw material crush, the crushed size of raw material should be less than 5 mm. To ensure raw material size is no more than the diameter of the pellet size and the size of die hole. Otherwise it will affect the production capacity of biomass pellet machine, even not discharge the pellet.

- Make the crushed material drying, water requirement within the 8-15%. The too big or too small moisture content will affect the particle forming rate. If you feel bad control this, you can buy a humidity tester to test the moisture content, it is very cheap and very convenient also.

- After raw material handle well is the pellet making stage. The pellet making machine has two types, one type is flat die pellet machine, another type is ring die pellet machine. The flat die pellet machine is suitable for pressing strong glue material, such as crop stalks. But the ring die pellet machine is suitable for pressing the poor adhesion materials, such as wood chips, etc. No matter which type pellet making machine, it is worth noting that the feeding speed must be uniform, too slow will affect the production capacity, too fast will affect stoppage or crashing.

- The following stage is the cooling. The finished pellets which just came out from the machine are with the high temperature, so when you cool them by the cold wind, they are easy to crack; when you pile up the pellet, they are easy to catch fire. The best way is to be natural cooling, if the output capacity is too large, you will need to use cooling machine. The cooling machine can quickly make the pellet be cool, and can ensure the pellet look in good condition.

- The final step is to package. If you are using by yourself, after cooled you can directly collect storage, no need to packing. If it is for sale, the pellet will need weighing and packing.

Why choose GEMCO particles machine production line?

We have the factory, which is with the rich experience of producing pellet mill and pellet making machine production line.

Our technical engineers can customize complete sets of production lines according to customer’s need, we can provide the best design plan according to your workshop.

We have the special quality inspection department, the machines are with professionally strict quality testing before they leave the factory, which is to ensure product quality.

For the pellet machine production line, we can provide technical personnel on the spot to guide equipment installation and commissioning, and meanwhile we can training the operators for the buyer.

All our Equipments are with the quality warranty, we supply the free service within shelf life.