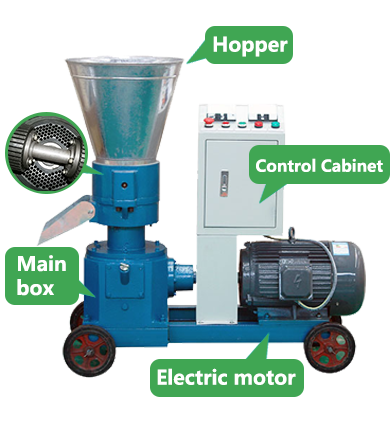

Small wood pellet mill is used to make biomass fuel with various raw materials like wood, crop straw, saw dust and bamboo shaving. It overcomes the difficulty to pelletize crude fibers and achieves satisfying effect. The main engine adopts high-efficiency belt drive, the feeding speed is adjustable to ensure stable input, and the drive parts adopts high-accuracy gears.

GEMCO small wood pellet mill is a combination of advanced manufacturing technique and premium assembly parts, guarantee you long service life and high production efficiency. scientific design makes it compact and safe, with low noise, good performance and beautiful appearance.

With county’s growing support to environment protection and sharp cutoff of fossil resources, biomass energy emerge as a green and economical substitute. To make biomass fuel at home, small wood pellet mills are indispensible. GEMCO provide wood pellet machines with different power plants. They can make full use of your biomass wastes and greatly save your fuel cost.

With the growing cost of grain and fossil fuel, people are looking for ways to recycle crop wastes and reduce their reliance on fossil fuel. With wood pellet mill they can process rice husk into fodder to feed animals, or process wood shavings into fuel to take the place of coal. Therefore, wood pellet machines become popular among customers.

The significance of biomass energy application

In terms of energy security, it can relieve the stress of resource shortage.

With regard to environment, it can improve the ecological environment.

Adopting biomass fuel can stimulate the growth of farmer’s income, improve rural condition, and accelerate urbanization progress.

Developing renewable energy drives social development. It is helpful to adjust economic structure, upgrade the development mold, and create jobs.

The raw materials are fed in vertical direction, and directly reach to pelletizing zone.

Compact structure and small size make it suitable for various working environment, with high portability.

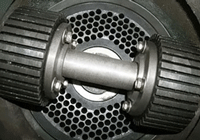

You can choose flat die with different sieve pore to adapt to different raw materials and achieve best pelletizing effect.

Small wood pellet machine adopts flat die structure. There are rotating roller and rotating die two type for you to chose from. Both can distribute the raw materials uniformly.

You don’t need to add any liquid or additives to the raw materials, for the high pressure and temperature is enough to mold them into hard pellets.

The roller and flat die are made of superior alloy steel, which can sustain high pressure so as to process hard materials. Meanwhile, they bear longer working life.

small wood pellet mills?

Start the machine, and feed processed raw materials into the hopper. They will be pressed into pellets by roller and flat die. Feed material slowly and gradually, and never fill up the hopper, in case the excessive pressure damages the flat die.

If the raw materials in hopper stops going down, never scope out them with your hands, or they may get hurt by the machine. You can scope with a batten or turn off the machine.

small wood pellet machine

Once a month is recommended. Figure out the wear and tear in components. Fix the defects once you find them, and never use it when something is wrong.

Keep the machine clean and dryEnsure there are no acid substance or corrosive gas in the room.

When a processing work completes, turn off the machine and clean the remnant wood chips in it with a brush. This is to facilitate the operation for next time.

Get Price NowOur honor

- China Association Of Rural Energy Industry(CAREI)

- China Flat die biomass briquetting technology standard-making group

- ISO9001 international quality system and EU CE Certification

- 10 patents on biomass briquetting and flat die pellet press

- Chinese customs class A enterprise, over 80% products for export

- High quality supplier for made-in-china.com and Alibaba

Workshop outside

Workshop outside  Process of making flat dies

Process of making flat dies Our workshop

Our workshop  Finished pellet press for sale

Finished pellet press for sale Well packaged pellet presses

Well packaged pellet presses